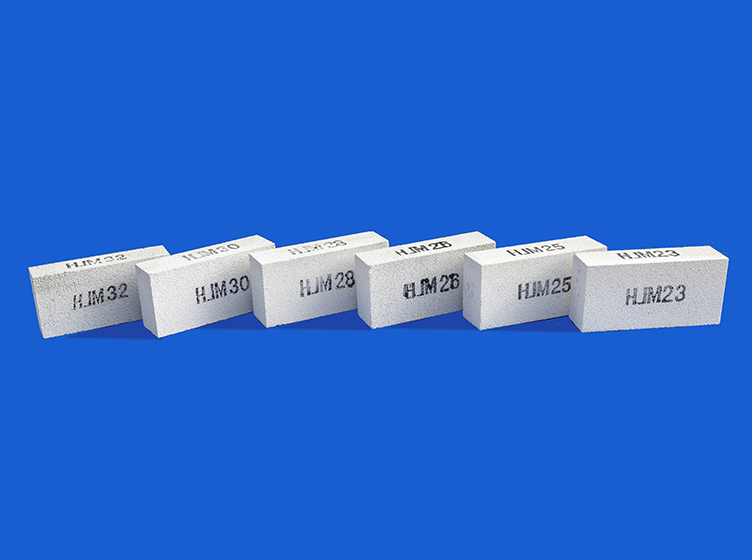

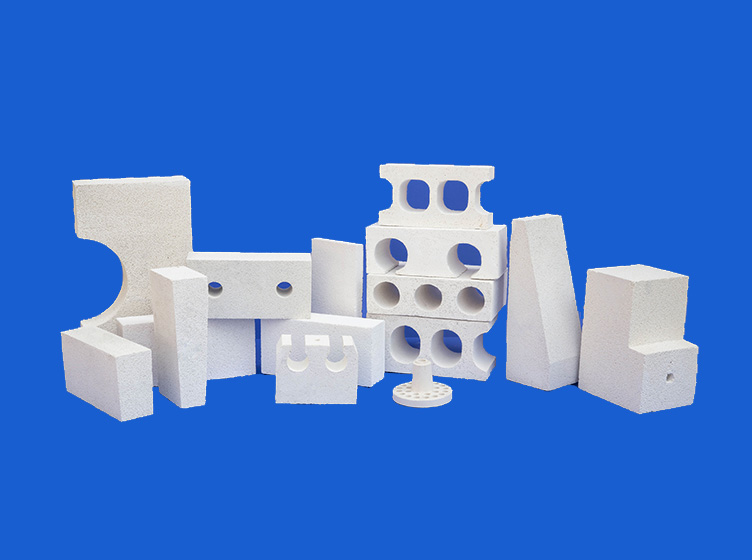

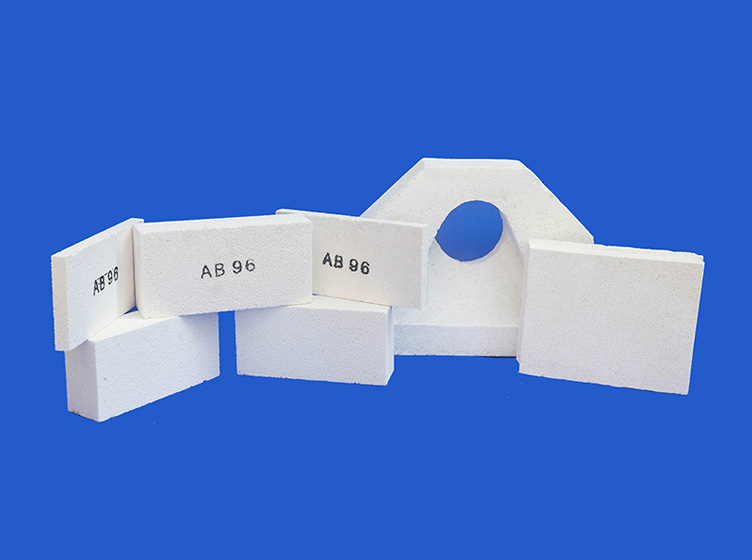

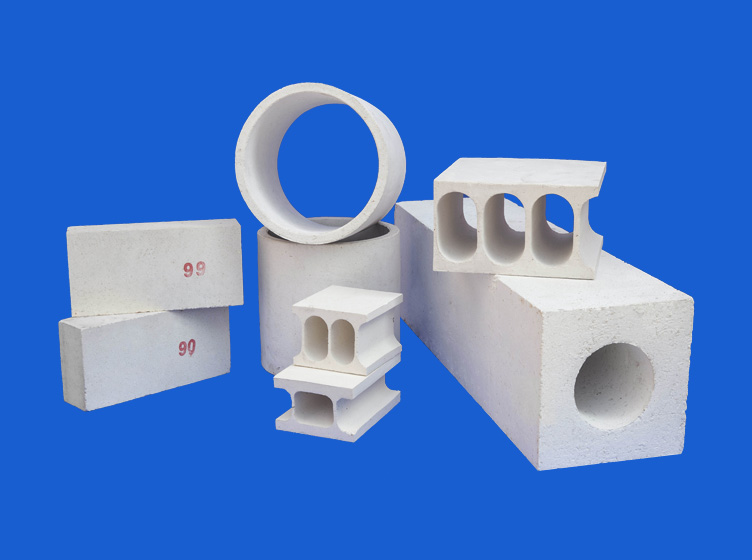

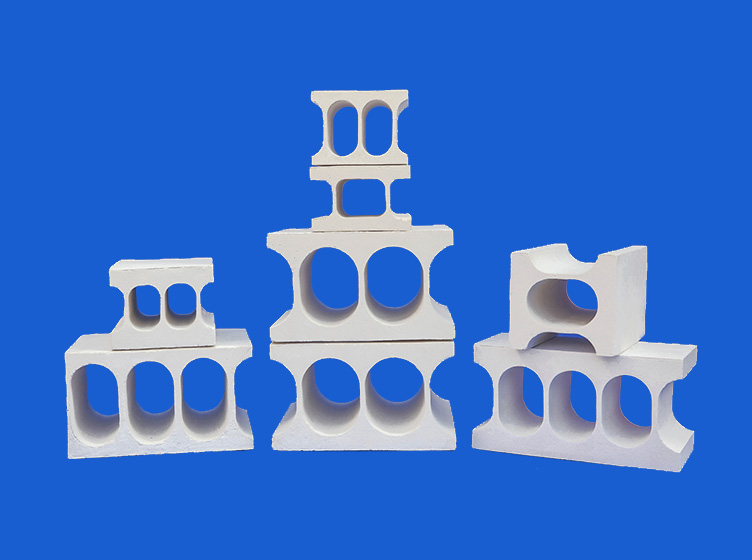

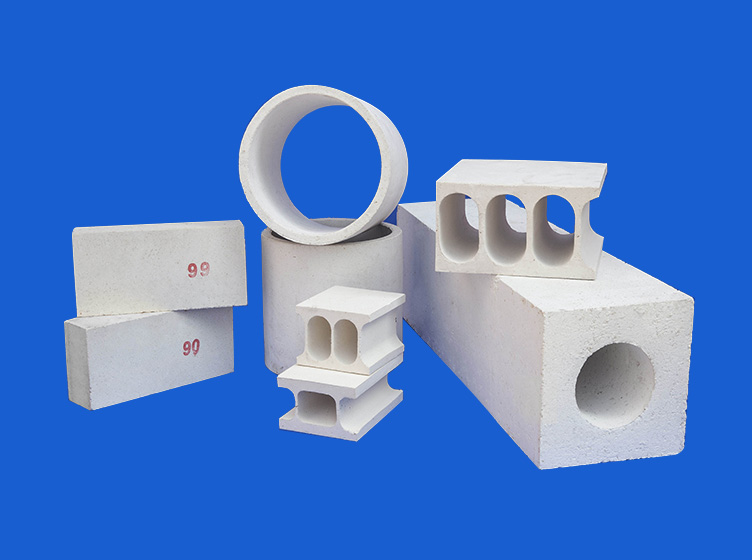

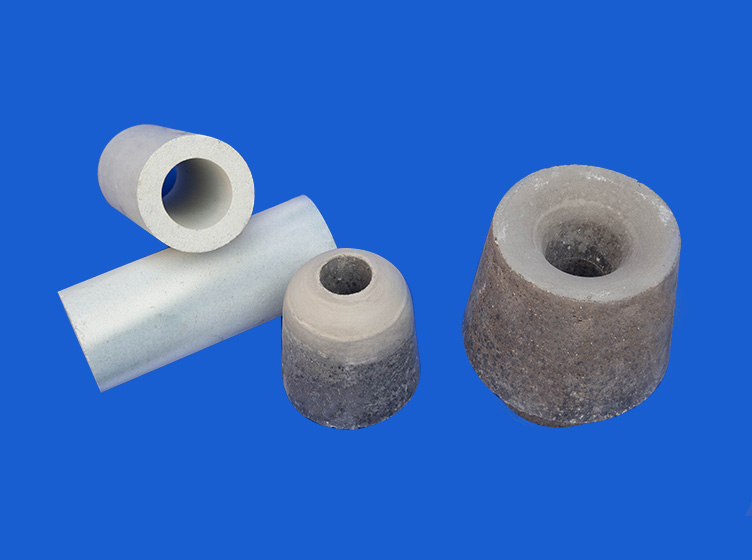

We are able to produce different levels of insulating firebricks and high refractory firebricks, with application temperatures from 1200℃ to 1800 °℃. Each product is developed specifically to meet the thermal and physical requirements of various industrial kilns.

Read MoreChina Non-standard Refractory Brick Manufacturers and Custom Shaped Brick Suppliers

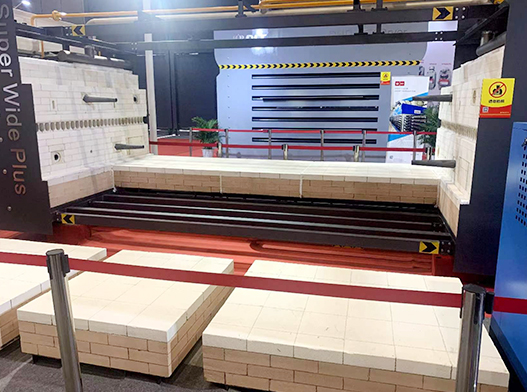

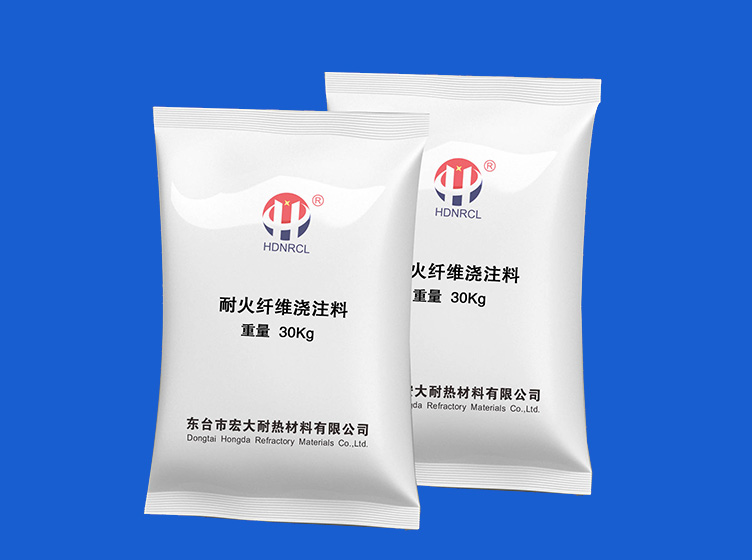

dedicated to the research and development of high-grade insulating refractory products, specializing in the petrochemical, metallurgy, ceramics, new energy, electronics, mechanical heat treatment and other industries. It provides high-quality HJM series of insulating refractory products and amorphous castables.Founded in 2008 with a registered capital of 20 million yuan, the company is located in Dongtai, Jiangsu Province, the home of China's refractory materials, with a beautiful environment and convenient transportation. We have a variety of domestic advanced manufacturing equipment, including automatic batching and molding lines, 1500 high temperature tunnel kiln, 1700 shuttle kiln, machining equipment, product firing temperature range from 1200℃ to 1800℃, the current production capacity of 20,000 tons of insulation materials.